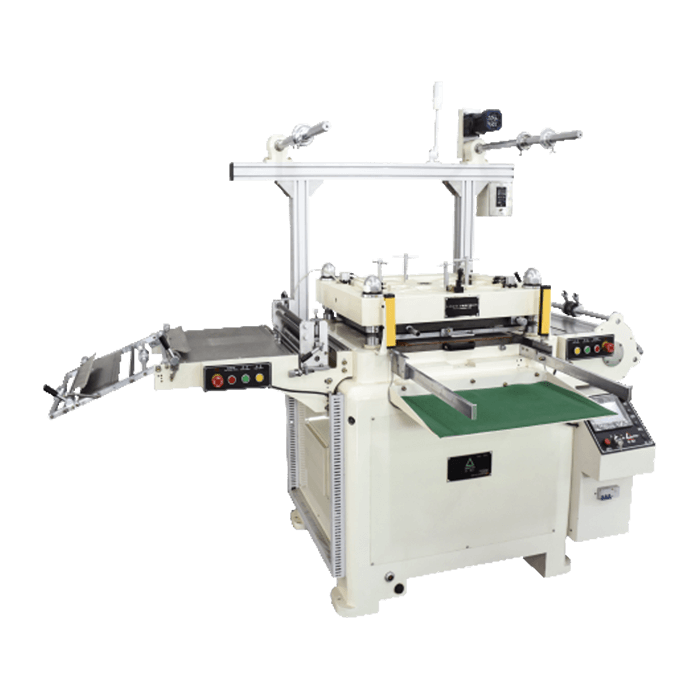

Standard configuration

|

|

LGZ-600 |

| Feeding width |

MM |

520 |

| Maximum die cutting area |

MM |

500*580 |

| Die cutting speed |

pcs/h |

8000 |

| Stroke adjustment amount |

MM |

9 |

| Cross cutting pressure |

T |

15 |

| Lubrication method |

|

Automatic circulating oil supply |

| Pressure adjustment method |

|

Automatic pressure adjustment and automatic locking |

| Choose a knife mold |

|

Wooden board mold, rubber board mold |

| Total power |

KW |

AC380V 7.5KW |

| Dimensions |

MM |

2700*1900*2000 |

| Machine weight |

KG |

2500 |

Features and function description:

1. The upper plate of the upper mold base adopts a frame locking type: the upper template is lighter, and the upper and lower templates are easy to replace the knife molds, so as to facilitate the operation of the starter (the upper template of the die-cutting machine on the market is composed of a whole aluminum plate, which causes the starter to load and unload the knife Increased difficulty);

2. Cylinder locking method: Four cylinders are controlled by one control key to lock the upper template, so as to achieve a balanced effect (the locking method of the template on the die-cutting machine on the market is a hand screw lock machine, resulting in inconsistent tightening of the upper template. Make the machine balance difficult to achieve the desired effect);

3. Mechanical pressure and pressure are controlled by computer touch: pressure and pressure are controlled by computer servo with high precision, which is convenient for the master to add pressure and operate the whole machine to automatically supply oil;

5. Suitable for punching of various roll and sheet materials;

6. The computer servo numerical control system is used to pull and feed materials, which can be used as a full-break/half-break type, waste discharge, high precision, low noise, fast speed, and anti-scratch function;

7. It can be used for secondary die-cutting and punching, which is widely used in the electronics industry and the printing industry;

8. The secondary positioning die-cutting function can be customized according to customer requirements.

Available molds: engraving mold, etching mold, rubber mold, wood mold