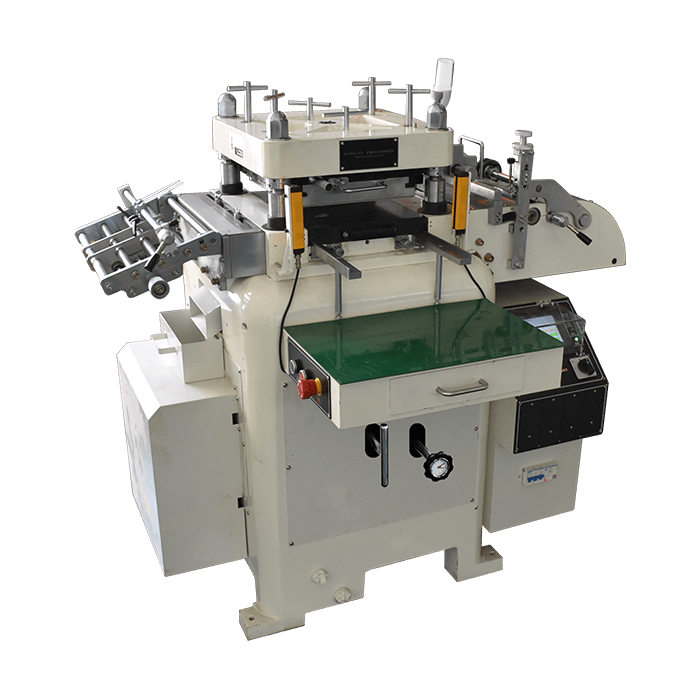

Standard configuration

1. Small Rabo professional set;

2. Manual pressure regulating die-cutting host;

3. Equipped with one piece of standard upper die thick plate;

4. Equipped with one piece of standard lower die thick plate;

5. Equipped with a three-color light;

6. The touch screen has a protective cover;

7. Metal mold blanking hole 200°140;

8. Light curtain for operating side safety protection;

9. QDC mold can be installed, the closed height of QDC mold is 100mm;

|

|

LFD-300 |

LFD-350 |

| Feeding width |

MM |

310 |

350 |

| Maximum die cutting area |

MM |

300*260 |

345*290 |

| Production speed |

pcs/h |

1800-18000 |

1800-18000 |

| Stroke adjustment amount |

MM |

24 |

24 |

| Cross cutting force |

T |

8 |

8 |

| Pulling accuracy |

MM |

±0.1 |

±0.1 |

| QDC set balance accuracy |

MM |

±0.05 |

±0.05 |

| Lubrication method |

|

Automatic lubrication system |

Automatic lubrication system |

| Frame casting |

|

HT250 high quality gray iron |

HT250 high quality gray iron |

| Total power |

KW |

AC200V 3KW |

AC220V 3KW |

| Dimensions |

MM |

L1500*W1100*H1560 |

L1500*W1100*H1560 |

| Net weight of the machine |

KG |

1400 |

1450 |

Features and function description:

1. The pressure stability is high, and the pressure change will not be affected by the excessive pause time during the processing of the product.

2. The function of sticking to the mold, replacing the traditional hand crank to mold, can independently set the single pressing distance of the upper mold to the mold, the minimum distance is 0.01mm, and the mold can be inching or linked.

3. Double servo system control (CNC feeding precision, CNC host speed control).

4. The main engine is powered by a high-speed and large-inertia servo motor with low noise and large torque.

Available mold: wood mold, laser mold, corrosion mold, engraving mold, hardware mold, QDC mold