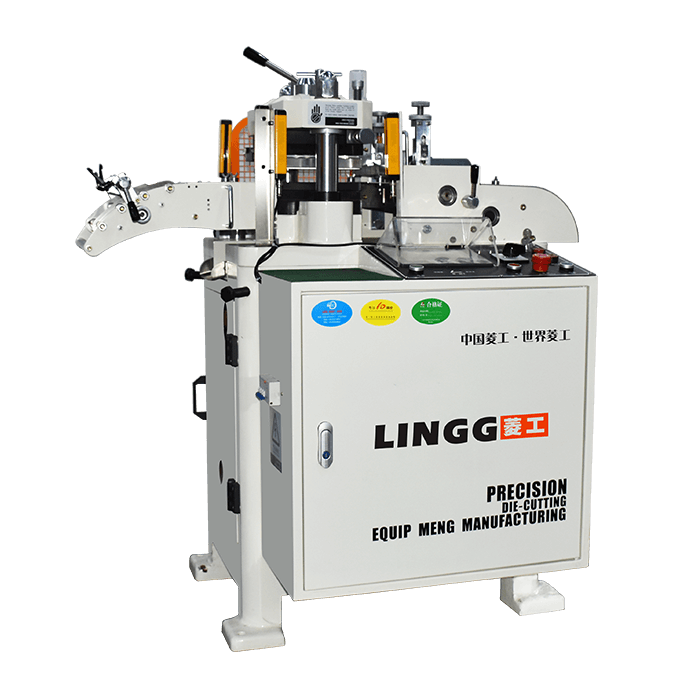

Standard configuration

1. Small Rabo bag with tape sleeve punching, military group small Rabo;

2. Fully intelligent die-cutting host;

3. Equipped with one piece of standard upper die thick and thin plate;

4. Equipped with a standard template;

5. With a three-color cigarette;

6. The touch screen has a protective cover;

7. QDC mold closing height: 100mm;

8. Metal mold blanking hole 100*100;

9. The touch screen has a protective cover;

10. Light curtain for operating side safety protection;

|

|

LD-200 |

| Feeding width |

MM |

220 |

| Maximum die cutting area |

MM |

200*180 |

| Production speed |

pcs/h |

1800-20000 |

| Stroke adjustment amount |

MM |

24 |

| Cross cutting force |

T |

5 |

| Pulling accuracy |

MM |

±0.1 |

| QDC set balance accuracy |

MM |

±0.05 |

| Lubrication method |

|

Automatic lubrication system |

| Frame casting |

|

HT250 high quality gray iron |

| Total power |

KW |

AC380V 4KW |

| Dimensions |

MM |

L1200*W1000*H1350 |

| Net weight of the machine |

kg |

1000 |

Features and function description:

1. Equipped with storage memory function, it can store 99 material numbers. The mold adjustment is completely digital, and it can accurately stay at the set parameter position, accurate to 0.001mm; this equipment is easy to operate and is completely digital, which saves mold adjustment. Time, material saving, and various parameters have reached the international leading level.

2. The pressure stability is high, and the pressure change will not be affected by the long pause time during the processing of the product.

3. Double servo system control (CNC feeding precision, CNC host speed control).

4. Stepping motor plus encoder control (numerical control plus, decompression control).

5. The main engine is powered by a high-speed and large-inertia servo motor with low noise and large torque.

6. Fully automatic digital pressure regulation, convenient and fast, the accuracy of pressure and pressure can be adjusted to 0.001MM, and the adjustment accuracy is high.

Available mold: wood mold, laser mold, corrosion mold, engraving mold, hardware mold, QDC mold