Who are we

Linggong Industry-

high-end intelligent technology overall solution provider2006year

10000m²

1000+

6people

Smartphone

Medical equipment

Automotive Industry

Digital products

Aerospace and aviation

What we can provide

Our core competitiveness

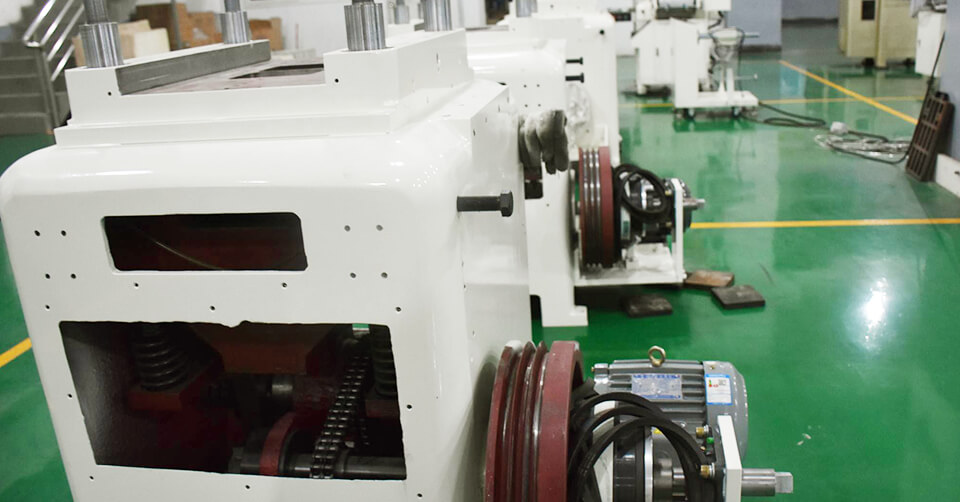

The body of our equipment uses integral castings, which are cast from HT520 high-quality gray iron, and the thickness of the body castings is 3-5mm thicker than the common thickness in the market.

In addition, the internal structure of our equipment has been reasonably designed, and the internal space of the equipment is reasonably used, making the equipment size smaller than the general die-cutting equipment on the market, which is conducive to the more reasonable use of site space for processing enterprises.

The body of our equipment uses integral castings, which are cast from HT520 high-quality gray iron, and the thickness of the body castings is 3-5mm thicker than the common thickness in the market.

Our die-cutting equipment has a memory storage function, which can store 99 material numbers. When performing the die-cutting conversion of two different products of A and B, the adjusted data (including pressure, jump distance, etc.) can be stored in the equipment when the A product is die-cut, and after the B product is die-cut, If you need to die-cut product A, you only need to enter the stored part number code on the operation page, and the device can automatically adjust back to the data when die-cutting product A, with an accuracy of ±0.01.

Quick response:24-hour after-sales consultation, promised to respond within 2 hours, and send maintenance personnel to the customer site to solve the problem within 24 hours.

Parts Inventory: It has a complete inventory plan for die-cutting parts, and the whole parts can be called directly, and the after-sales is faster.

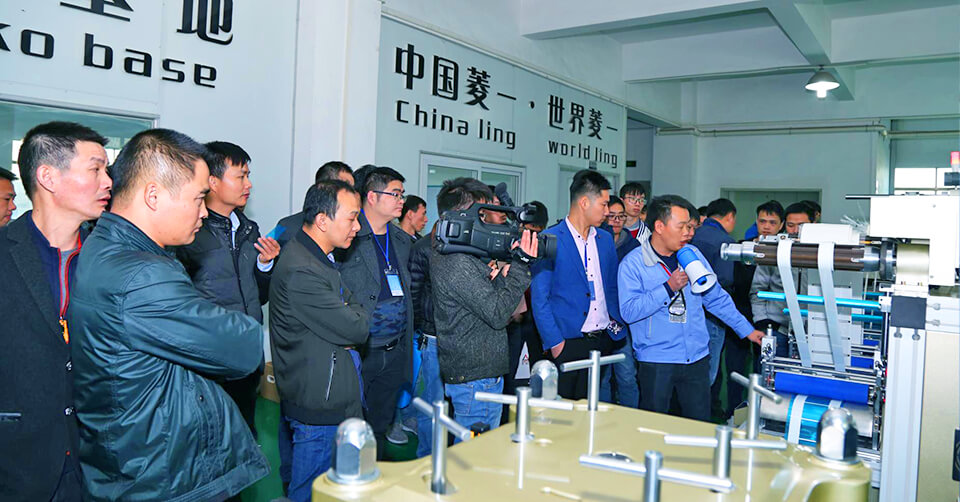

A grand meeting of the die-cutting industry led by die-cutting equipment and die-cutting technology is held every year. Industry leaders: Foxconn, BYD, Intellectual Power, Tianma, Holitech, China Optoelectronics, Lingsheng Group, etc., all visited and studied. It can be seen that Linggong Industrial's die-cutting process is sufficient to support and lead the demand of the current market.

Machine sound casting

Appearance design

Pay attention to materials

Memory storage

Service support

Technical exchanges

Long-term partner

LinggongFocus Dynamics

Follow me Tik Tok

Contact information