The laminating machine has also ushered in a new market in the mobile phone repair industry, but there are many users, because they usually do not pay attention to the maintenance of the laminating machine equipment, which greatly reduces the life of the equipment, but it appears when it is used. Various failures. The effect of LCD screen pressure is poor, bubbles are large, and so on. Usually these are the problems that are not paid attention to in maintenance, and it is easy to damage the original. So how to operate and maintain the laminating machine correctly? The following is introduced by the staff:

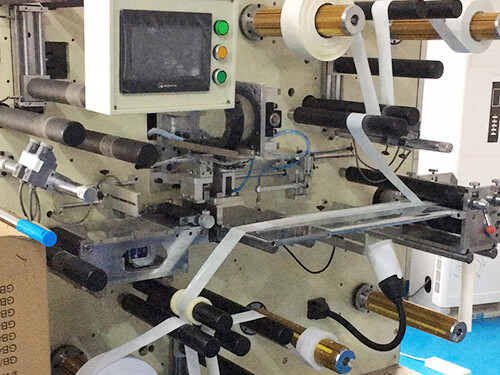

1. It is best to run at a low speed during trial production. After familiarizing with the performance of the machine, the production speed can be gradually increased, which can better ensure production safety and product embossing quality.

2. During operation, the correct control of temperature and pressure is very important equipment. If the control is not good, accidents are prone to occur, and even the laminating machine may damage the machine. When heating embossing and setting, you can control the problem according to the material characteristics. Generally, the temperature can be controlled between 40-90℃. Do not use ultra-high temperature for embossing and three-dimensional printing to prevent discoloration or deformation of the printed product and avoid rollers. The body deforms due to the influence of high temperature. The working pressure during embossing should be controlled in the range of 3-8mpa according to the thickness and density of the printed material. It is not necessary to blindly increase the pressure for the pursuit of high-definition embossing effect, so as to avoid pressure due to excessive pressure The roll is deformed.

3. Pay attention to the relationship between machine speed, temperature and pressure and the embossing effect. Generally speaking, in e-commerce, when the laminating machine is slow, the temperature is high, and the pressure is high, the embossing effect is relatively good, but it must be moderate, otherwise, it will affect the embossing quality of the product. For the layout of materials with high tightness and good stiffness, the machine pressure can be appropriately greater.

4. In order to prevent deformation of the pressure roller, the pressure roller must be separated from the pressure when the machine is stopped for a long time. The operating procedure is: first loosen the oil circuit control valve to separate the pressure roller and the pattern roller to RIP, and then stop the machine.

5. When the laminating machine presses different patterns to replace the pattern roller, you can first loosen the 6 screws on the roller support beam, remove the transmission chain and the heating tube on the pattern roller, and then remove the bearing seats at both ends of the pattern roller. Remove the upper part, and then use a belt or a soft and flexible rope to put it on the drum and lift it up. For quality control during the disassembly process, do not use iron rollers or other hard objects to pry, pad and hit the surface of the pattern roller to prevent damage to the roller pattern.

6. If the pressure roller has obvious wear and deformation, it can be grinded to make it reach the center of the uniform pressure.