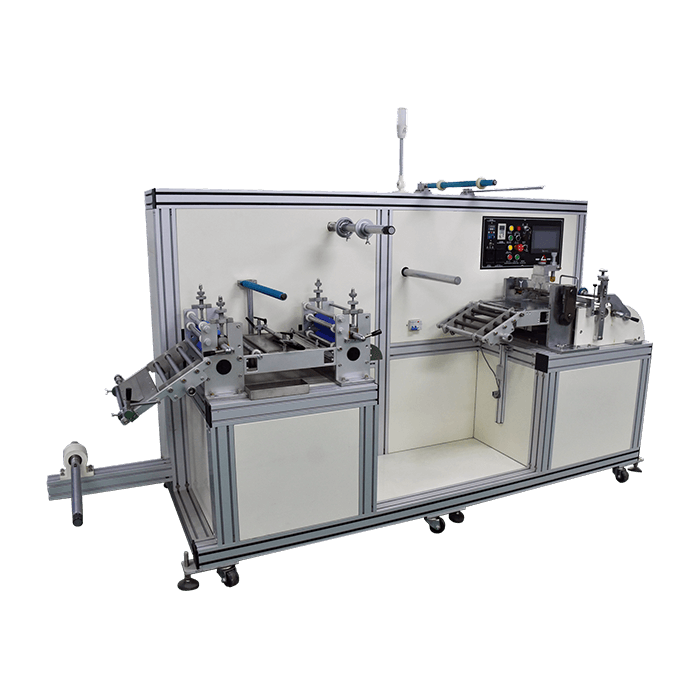

Standard configuration

1. Electromagnetic tension control of rewinding and unwinding axis, digital tension adjustment;

2. Two sets of servo electric eye control system;

3. Two put and one close;

4. Two sets of fitting devices;

5. Touch screen, PLC, servo system control

6. Alignment accuracy ±0.1mm;

Features

It adopts three control modes: inching, single-action, and linkage control, with simple and convenient operation and humanized control. The servo system pulls the material with high precision and precise alignment;

|

|

LDT-350 |

| Composite component |

Set |

2 groups |

| Retractable reel |

Set |

3 sets |

| Passing width |

MM |

300 |

| Point speed |

|

300pcs/h |

| Positioning accuracy |

MM |

±0.05 |

| Maximum point diameter |

MM |

600MM |

| Point accuracy |

MM |

±0.1 |

| Power supply |

KW |

380V |

| The appearance of the machine |

MM |

L2100*W1360*H1800 |

| Net weight of the machine |

KG |

800 |

Features and function description:

1. A fully automatic assembly machine for matching products such as dust-proof nets, speaker nets, and rubber rings with various specifications and multi-layer structures;

2. It adopts three control modes of inching, single and linkage control, simple and convenient operation, and humanized control. The servo system pulls the material with high precision and precise alignment;

3. The whole machine adopts aluminum profile structure, the equipment is stable and practical;

4. It can improve production efficiency, and the pasting efficiency can match the maximum punch of 300pcs/min of existing high-speed machines;

5. Full manual replacement, the whole machine and the combination can be used together to realize the automatic matching of the dust-proof net;

6. The biggest advantage of the dust-proof net on the pasting machine: saving labor, reducing the cost of manual use and management and control to save materials, the use of auxiliary materials and the loss of material adjustment can be effectively controlled;