The technical field of laminating machinery, specifically refers to a laminating machine that caters to two-layer boards.

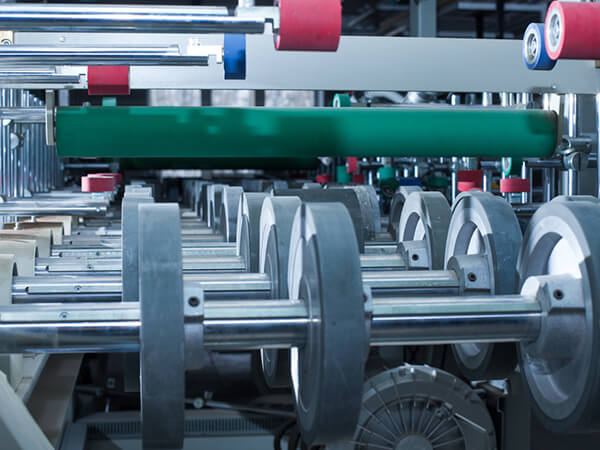

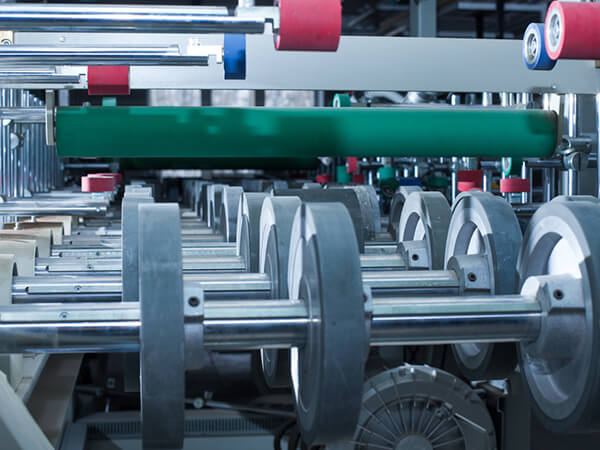

The laminating machine includes a first sheet unwinding device for placing the first sheet, a glue dispensing device, a second sheet unwinding device for placing the second sheet, and its heating, transportation, heating, pressurizing, and catering equipment. Heating, transportation, heating, charging and pressing cater to the equipment includes a motor, a heating wheel and its pressing roller according to the motor drive, in which the upper surface of the heating wheel produces an air-dried heating conveying zone and its charging and pressing caterpillar zone, in which the pressure The roller is located in the outside field of the charging and pressing caterpillar zone; the sheet placed on the first sheet unwinding equipment is passed through the dispensing equipment into the air-dry heating and conveying area on the upper surface of the heating wheel, and is transported on the heating wheel The lower and second plates are passed between the pressing roller and the heating wheel.

The laminating machine is one of the necessary machinery and equipment for the production of LCD screens. It is used in the post-process production of LCD screens to paste polarizers on the front and back sides of the formed LCD screen glass substrate according to the polarization viewing angle of the light. . In addition, the laminating machine is also suitable for touch parts and window maintenance to establish various composition processing processes, and can perform film/film. Film/B glass substrate, the film caters to the pressure sensitivity of various materials such as acrylic sheet. So what are the standard types of laminating machines?

Under normal conditions, the standard laminating machine is nothing more than two types: cold laminating and hot laminating.

Cold fit:

Cold bonding is mainly to release the pressure, so as to cater to the way that the pulsation damper is bonded together according to the polyurethane resin. The key to cold bonding is suitable for catering to heat-sensitive materials. For example, the black ink of some color printers melts when exposed to heat, and some printers use thermal printing paper for copying. In this situation, a cold laminator is a better choice.

Heat bonding:

Thermal bonding is the most common way to cater. According to the different raw materials that cater to, it is generally necessary to heat up to a higher temperature. Thermal bonding can show good catering characteristics, and the products after catering are more resistant to wear and not easy to crack. The heat bonding method is suitable for raw materials that will not be harmed by heating.