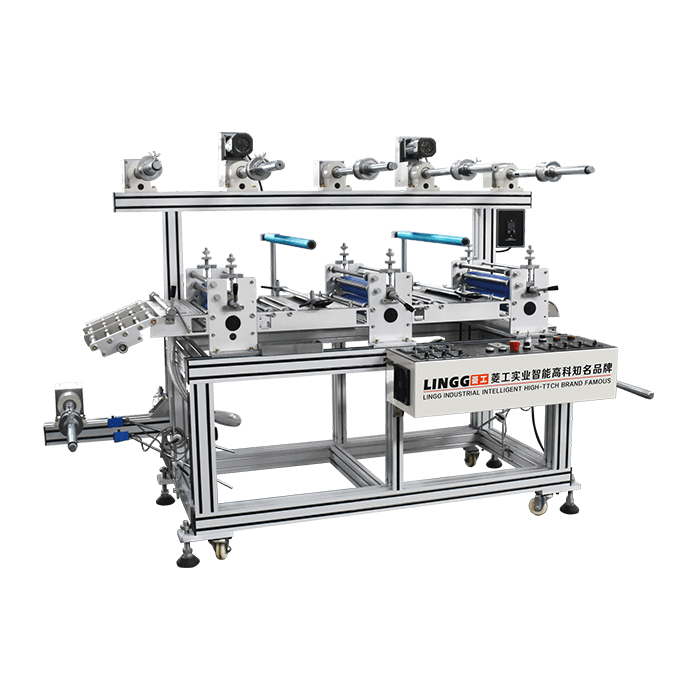

Standard configuration

1. Electromagnetic tension control of rewinding and unwinding shaft, digital display tension adjustment;

2. Diffuse reflection online control combination, the front diffuse reflection fixed rod is lengthened;

3. Magnetic powder tension control for the first seat of the lamination seat;

4. Four releases and three collections;

5. Fitting width 350-450MM;

6. Speed 40m/min;

7. Rotating small electric box;

Using features

Feeding—fitting—discharging waste—fitting—discharging waste—rewinding;

Features

Multiple sets of laminating adhesive films can be used for laminating and discharging multiple and multi-layer materials. The laminating tension of the materials is fully controlled by the magnetic powder tension controller to ensure the flatness of the laminating materials. Each group of laminating rubber rollers The pressure and gap of the upper and lower rubber rollers can be adjusted independently, and the operation is simple and convenient.

|

|

LTJ-350-3 |

LTJ-450-3 |

| Composite component |

Set |

3 |

3 |

| Unwind the scroll |

Set |

4 |

4 |

| Rewinding reel |

Set |

3 |

3 |

| Abdominal width |

MM |

350 |

450 |

| Abdominal speed |

|

0~40m/min variable frequency stepless speed regulation |

0~40m/min variable frequency stepless speed regulation |

| Positioning accuracy |

MM |

±0.1 |

±0.1 |

| Rewinding diameter |

MM |

600 |

600 |

| Tension |

|

Each axis independent electronic tension control automatic/manual |

Each axis independent electronic tension control automatic/manual |

| Power supply |

KW |

Single phase 220V/1KW |

Single phase 220V/1KW |

| The appearance of the machine |

MM |

L2400*W1250*H1560 |

L2400*W1350*H1560 |

| Net weight of the machine |

KG |

400 |

450 |