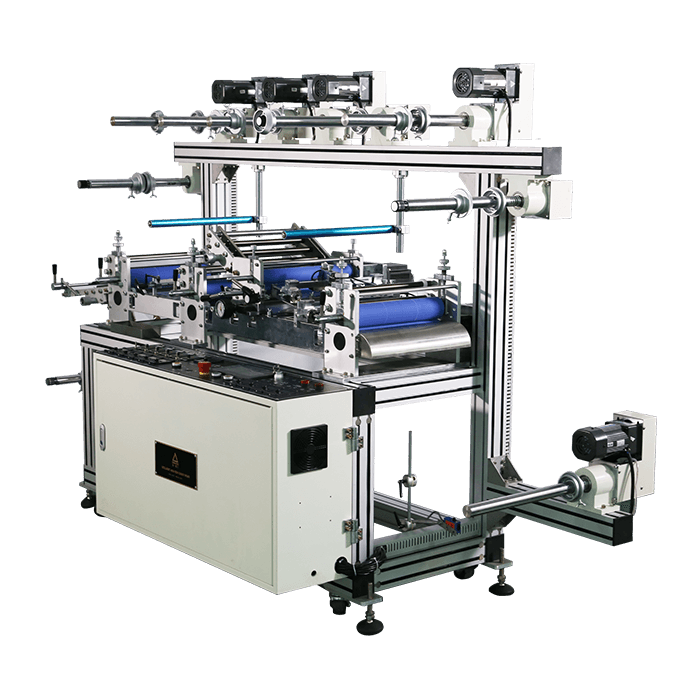

Standard configuration

1. Electromagnetic tension control of rewinding and unwinding shaft, tension adjustment by number;

2. Magnetic powder tension control for the first seat of the lamination seat;

3. Four releases and five collections;

4. Fitting width 350MM;

5. The highest speed is 6000PCS/H;

6. Rotating small electric box;

7. Two sets of servo control system;

8. 2 sets of electric eye color tracking device;

Using features

Feeding—fitting—discharging waste—fitting—reposting—fitting;

Optional configuration

Electromagnetic tension control and mechanical tension control can be selected for the rewinding and unwinding shaft;

Features

Multi-group lamination film can be used for lamination, waste removal and reposting of multiple and multi-layer materials; the lamination tension of the material is fully controlled by the magnetic powder tension controller to ensure the flatness of the lamination material, and each group is lamination The rubber rollers can independently adjust the force and gap between the upper and lower glue reports, and the operation is simple and convenient; "One machine with multiple functions, can be used as a laminating machine or as a reposting machine";

|

|

LTF-350-4 |

| Composite component |

Set |

4 |

| Unwind the scroll |

Set |

5 |

| Rewinding reel |

Set |

4 |

| Abdominal width |

MM |

350 |

| Abdominal speed |

|

30M/MIN |

| Positioning accuracy |

MM |

±0.1 |

| Rewinding diameter |

MM |

600 |

| Tension |

|

Each axis independent electronic tension control automatic/manual |

| Power supply |

KW |

220V/4.5KW |

| Machine weight |

KG |

500 |

| The appearance of the machine |

MM |

L2700*W900*H1500 |